Communication between the industrial design and buy autodesk inventor 2023 groups at many companies can be painful at best. Industrial design, whose job it is to make the product appealing to the consumer, passes their concepts to engineering, whose job it is to make the product manufacturable. The problem is that industrial design typically uses one set of design tools while engineering uses another.

In the ideation stage when ideas are hatched and products are conceived, direct modeling is most commonly used. Direct modeling is 3D modeling that does not require the structure and specific relations that are necessary during the engineering stage. Direct modeling allows for quick and dramatic changes to a design’s geometry without the dimensional accuracy that is needed to produce the final product. This freedom of design greatly increases the speed and flexibility of the design so that multiple ideas can be created and evaluated.

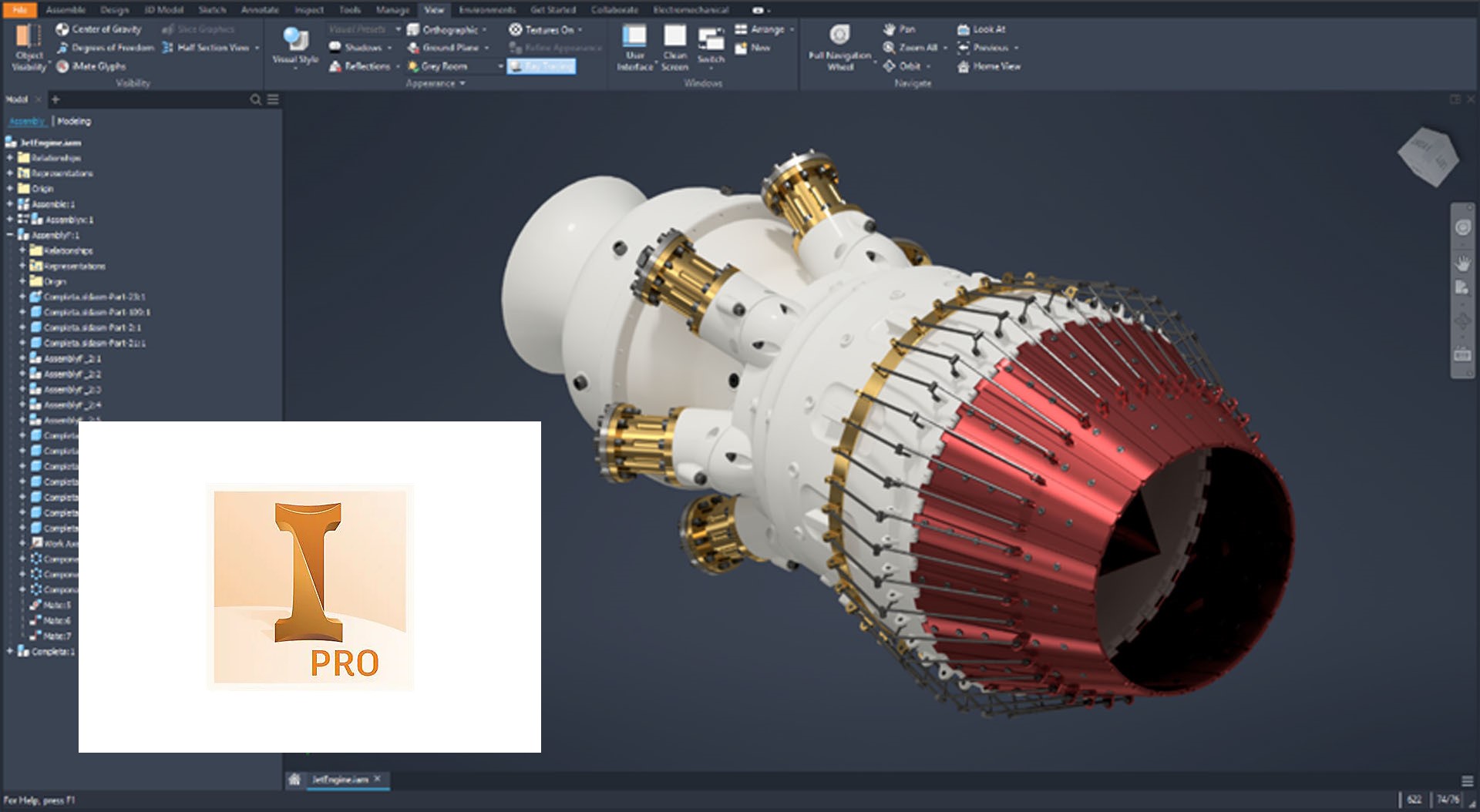

In the engineering stage when a concept has been chosen and it is now time to solidify the dimensions and features of the design, parametric modeling is used to capture the design intent while providing all of the information necessary to manufacture and check the final product. Unfortunately, the buy autodesk inventor 2023 that provide the flexibility of direct modeling and those which provide parametric modeling and workflows do not communicate well. Often times, it is necessary for engineering to duplicate the efforts of industrial design in order to transition their concepts into a manufacturable model. However, a new concept has been hatched to bridge this disconnect between ideation and engineering. That concept is Autodesk Inventor Fusion Technology.

Autodesk Inventor Fusion Technology unites direct and parametric workflows. With Fusion buy autodesk inventor 2023, changes can be made to a single digital model that is shared by both engineering and industrial design. Features added or changed are saved in the model’s parametric feature history, maintaining the design intent of engineering while allowing the fluidity required by industrial design. This seamless collaboration of digital knowledge bridges the disconnect that exists between ideation and engineering and represents a real and significant improvement in productivity because of the elimination of the time required to remodel concepts as they pass back and forth between departments.

Fusion Technology is a concept whose time has come. It is still budding technology, and uniting two very different modeling practices is a monumental undertaking. However, when corporate giants the likes of Autodesk begin to sink research dollars into a task, it is not just to help mankind, but because there is a real need to be filled and consequently real dollars to be made. Watch for this technology to gain momentum as industry begins to realize the productivity gains and shorter product development times that it has to offer.