In the realm of manufacturing and engineering, precision and consistency are paramount. Achieving the desired level of accuracy in various industrial processes often relies on the use of specialized components, and one such component that plays a pivotal role is the فنر قالب Spring. These unassuming coil springs might not grab the headlines, but they are the unsung heroes behind many manufacturing operations, ensuring that molds, dies, and tools function smoothly and efficiently.

Understanding Mold Springs

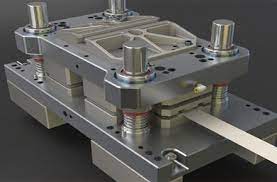

Mold springs, also known as die springs or ejector springs, are mechanical devices designed to exert a specific force when compressed. They are typically made from high-quality materials like chrome-silicon or chrome-vanadium steel, chosen for their exceptional durability and resistance to corrosion. What sets mold springs apart is their unique helical shape, which allows them to absorb and distribute loads evenly, making them ideal for applications where a constant, predictable force is required.

Applications in Molding and Tooling

One of the primary applications of mold springs is in the field of injection molding. In this manufacturing process, molten material is injected into a mold cavity under high pressure to create a wide range of products, from plastic toys to automotive components. Mold springs play a critical role in ensuring that the mold remains closed with the required force during injection, preventing defects and maintaining product quality.

Similarly, mold springs find extensive use in metal stamping dies, where they assist in maintaining the necessary pressure to shape sheet metal into specific forms. These springs are also employed in various types of machinery, including presses, die-cutters, and extrusion machines, where their consistent force ensures the precision and longevity of these tools.

The Importance of Proper Selection

Selecting the right mold spring for a particular application is a nuanced process. Engineers and manufacturers must consider factors such as load requirements, working environment, temperature variations, and desired life expectancy. Mold springs come in a range of sizes and force ratings, denoted by color codes for ease of identification. Proper selection is crucial to ensure that the spring can endure the rigors of the application while maintaining its performance over time.